Keywords

7 KW

Low Load

Coil Form

Next Work

NSIC REGD

Run Button

dwell time

L& T Brand

180 Minutes

First layer

phase angle

1150 Degrees

extended use

Small cracks

Alarm Signal

closing door

cooling rate

New Materials

Heat Capacity

Triple Layer

Second layer

Operating Temp

Nano Materials

High Precision

explosive gases

Working Process

Metal Materials

Good Uniformity

Max Temperature

alumina coating

precise control

A-1” Grade Wire

Product Overview

GMP/CE CERTIFIED

Room Temperature

Brick insulation

PP Powder Coated

Protection Action

normal occurrence

Ceramic Materials

Longer Life Using

Long Service Life

SSR power control

Type Floor Model

Instrument Program

Research Institutes

broken thermocouple

refractory ceramics

Industrial Colleges

Thermocouple K type

Temperature Accuracy

The Furnace Material

The Kanthal A1 Grade

Electronic Components

Refractory door block

PID automatic control

temperature protection

PID Auto-Tune function

Zirconia Fiber Blanket

Semiconductor Materials

Heating Element Kanthal

Muffle Furnace 1400 type

necessary safety controls

current limiting resistor

99.7% purity Alumina tube

1260℃ ceramic fiber board

1430℃ ceramic fiber board

The Temperature Controller

Safety Protection Overheat

Precise Temperature Control

Box Type Resistance Furnace

Temperature Field Uniformity

1 programmable x 16 segments

Electronic Component Autonics

Daily Application Development

Other Industrial Laboratories

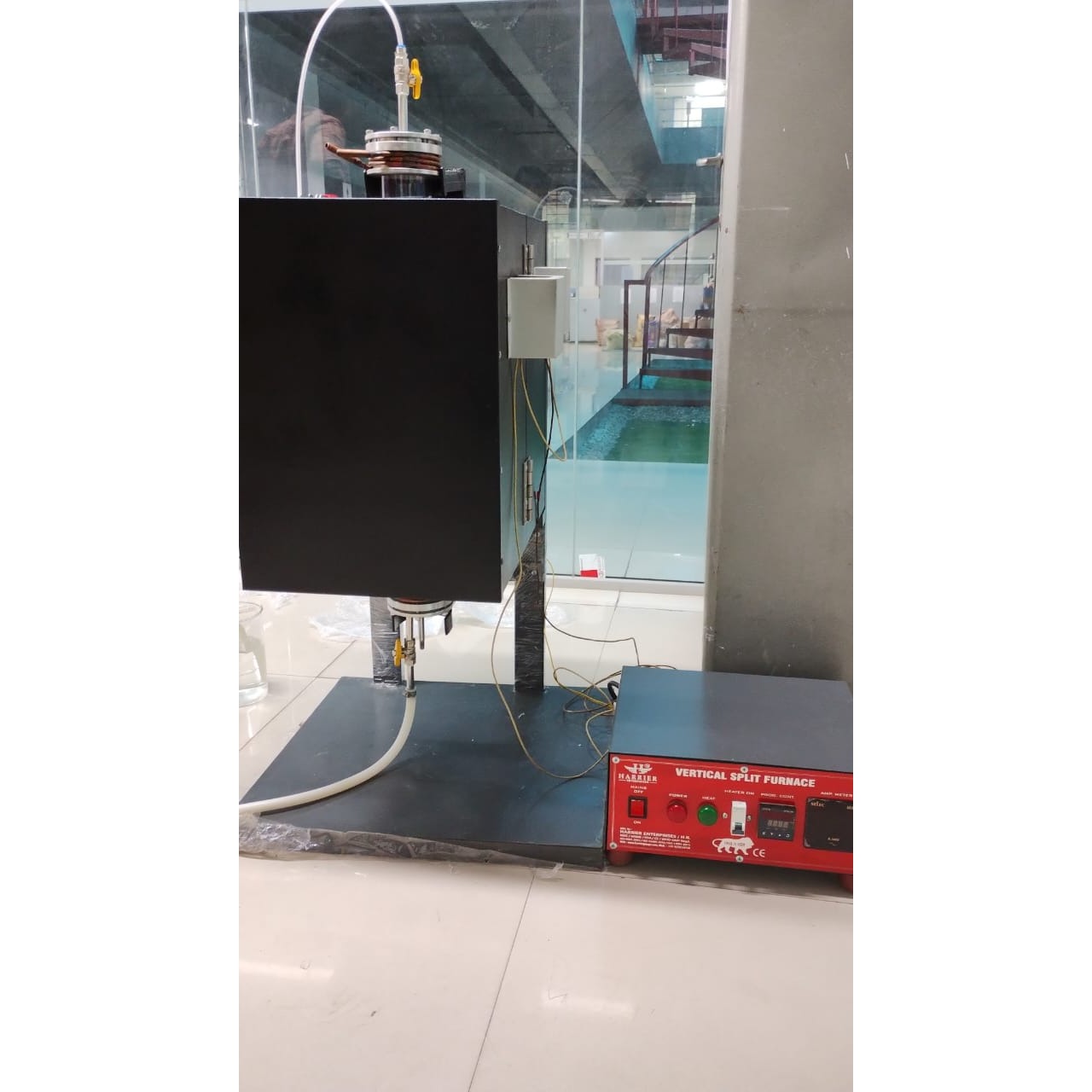

HE-SVTF 1200℃ Series Products

High-Quality Furnace Materials

MODEL HOT ZONE LENGTH Dia POWER

High-Quality Kanthal “A-1” Grade

Stable Temperature Control System

Microprocessor PID Control Module

1200°C Split Vertical Tube Furnace

Furnace Shell High Quality GI Sheet

L& T Electronics Brands Heating Rate

Thermocouple-Break Alarm Certification

Split Vertical Round Furnace 1200 type

Light weight ceramic Fiber wool insulation

High Temperature Heat Treatment Environment

Vacuum-Formed Alumina Ceramic Fiber Material

Constant Temperature Requirements Specification

High Quality Ceramic Fiber Zirconia Grade Thermal Insulation Material