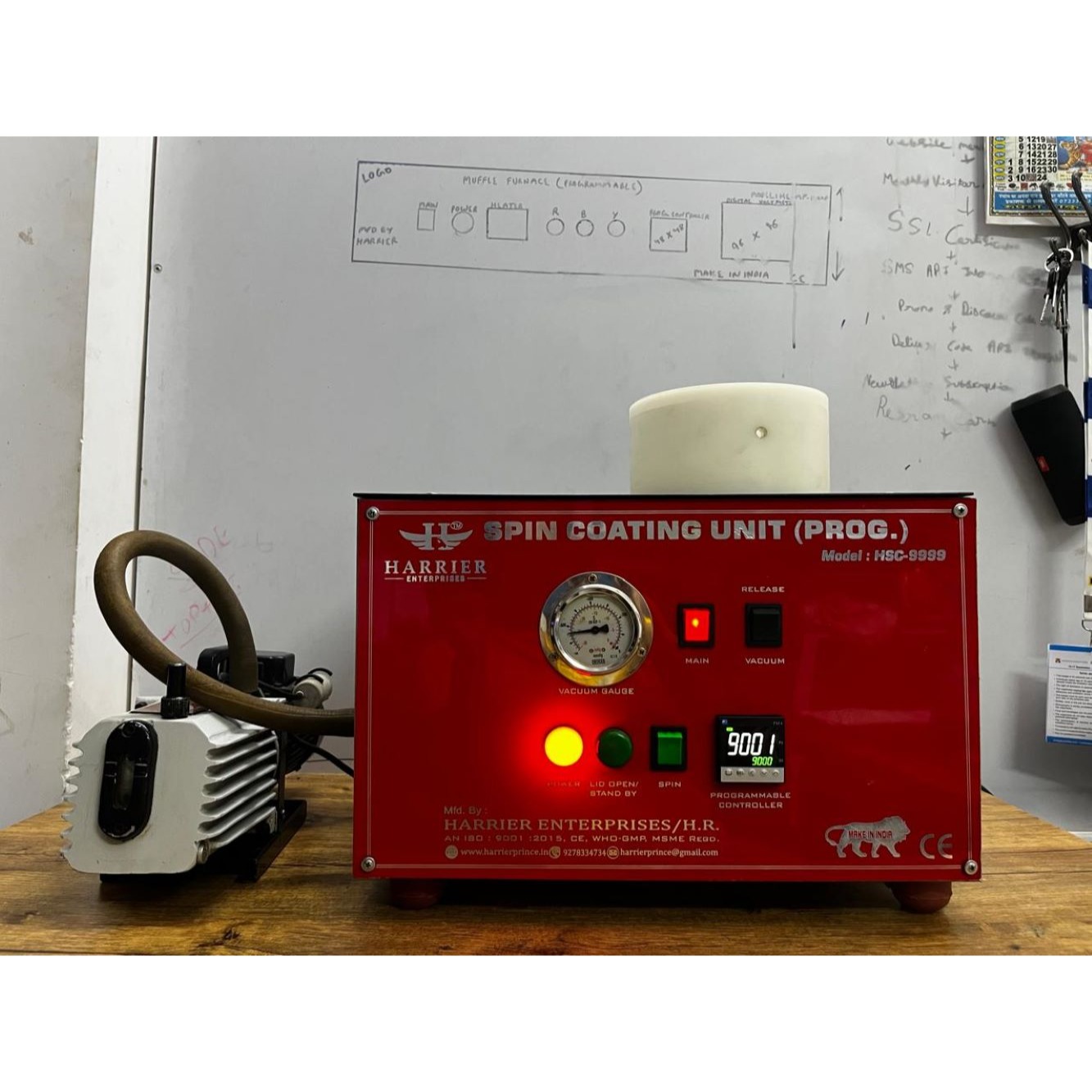

Fytronix Ix 9000 Spin Coater:-

Make: HE (NSIC Regd, MSME Regd, ISO 9001 – 2015/14001-2015/13485-2016/FDA/ GMP/CE Certified)

Model: HSC – 8000

Introduction

Anti-corrosion spin coater adopts PP chamber (Optional PTFE chamber), which is beautiful and sturdy in appearance, has excellent chemical stability and strong corrosion resistance, and can be used in various occasions requiring acid and alkali resistance and organic solvents. Anti-corrosion spin coater adopts advanced precision motor, the maximum speed can reach 6000 RPM / 8000 RPM/ 9999 RPM, which effectively guarantees the uniformity of film formation. In addition, the instrument adopts touch screen control and can preset the coating curve, which greatly simplifies the use process and reduces the learning cost. It is very suitable for laboratory purchase.

Application:-

The spin coater can coat liquid or colloidal materials on silicon wafers, crystals, quartz, ceramics and other substrates to form thin films. It is mainly used in photoresist spin coating, biological medium preparation, sol-gel method for polymer film production, etc.

Technical Specification: -

• Polypropylene Working Chamber (removable), size 6-inch dia, with transparent photo resist lid with interlock safety switch.

• 500 – 8000 RPM

• Accuracy<±0.5% of Full Speed

• Microprocessor Programmable Speed control with respect to time Preset editable programs of 8 program X 8 segments.

• Real time display of RPM, time and program stamps

• Nonvolatile program memory

• Input & control through soft touch key pad.

• Vacuum release switch

• Substrate size from 0. 04sq.inch (28 sq.mm) to 4.0 sq. inch (For glass substrate) & 20.0 sq. inch (for silicon

wafers)

• Vacuum chuck: derlin made circular substrate

holders of Dia

• 0.5”, 1”, 1.5”, 2.0” inch

• Microprocessor control A C brush less motor.

• Acceleration 2000 rpm/sec (Maximum) use settable.

• Calibration option.

• Vacuum Dial gauge.

• Frame: Epoxy coated MS.

• Facility for interlocking with Vacuum Pump.

• Tubing for Vacuum.

• Gas Purging Attachment for Nitrogen.

• Spill drainage facility

• To operate on 230V ± 10%, 1 phase 50 Hz AC only.

• Maximum Power 190W, Current 1.0 Amp.

With Vacuum Pump:

Model Technical Name Technical Parameters

HE115 N Flow rate 50 Hz 1.8CFM

51 l/min

60 Hz 2.0CFM

57 l/min

Ultimate vacuum Partial Pressure 2 Pa

Total Pressure 150 micron

Power ¼ HP

Inlet Port ¼” Flare

Keywords

¼ HP

60 Hz

50 Hz

4.0 sq

1 phase

20.0 sq

9999 RPM

6000 RPM

MSME Regd

NSIC Regd

Inlet Port

thin films

Full Speed

PP chamber

use process

Vacuum Pump

Vacuum chuck

learning cost

coating curve

maximum speed

500 – 8000 RPM

sol-gel method

silicon wafers

film formation

program stamps

Substrate size

Total Pressure

Current 1.0 Amp

glass substrate

size 6-inch dia

Epoxy coated MS

other substrates

organic solvents

150 micron Power

various occasions

alkali resistance

Vacuum Dial gauge

Real time display

Calibration option

Maximum Power 190W

soft touch key pad

colloidal materials

laboratory purchase

touch screen control

A C brush less motor

Vacuum release switch

Optional PTFE chamber

Microprocessor control

8 program X 8 segments

Gas Purging Attachment

Spill drainage facility

polymer film production

Technical Specification

interlock safety switch

photoresist spin coating

advanced precision motor

Nonvolatile program memory

Anti-corrosion spin coater

strong corrosion resistance

excellent chemical stability

Fytronix Ix 9000 Spin Coater

transparent photo resist lid

Polypropylene Working Chamber

biological medium preparation

time Preset editable programs

Ultimate vacuum Partial Pressure

silicon wafers

circular substrate holders

Microprocessor Programmable Speed control

Model Technical Name Technical Parameters HE115 N Flow rate