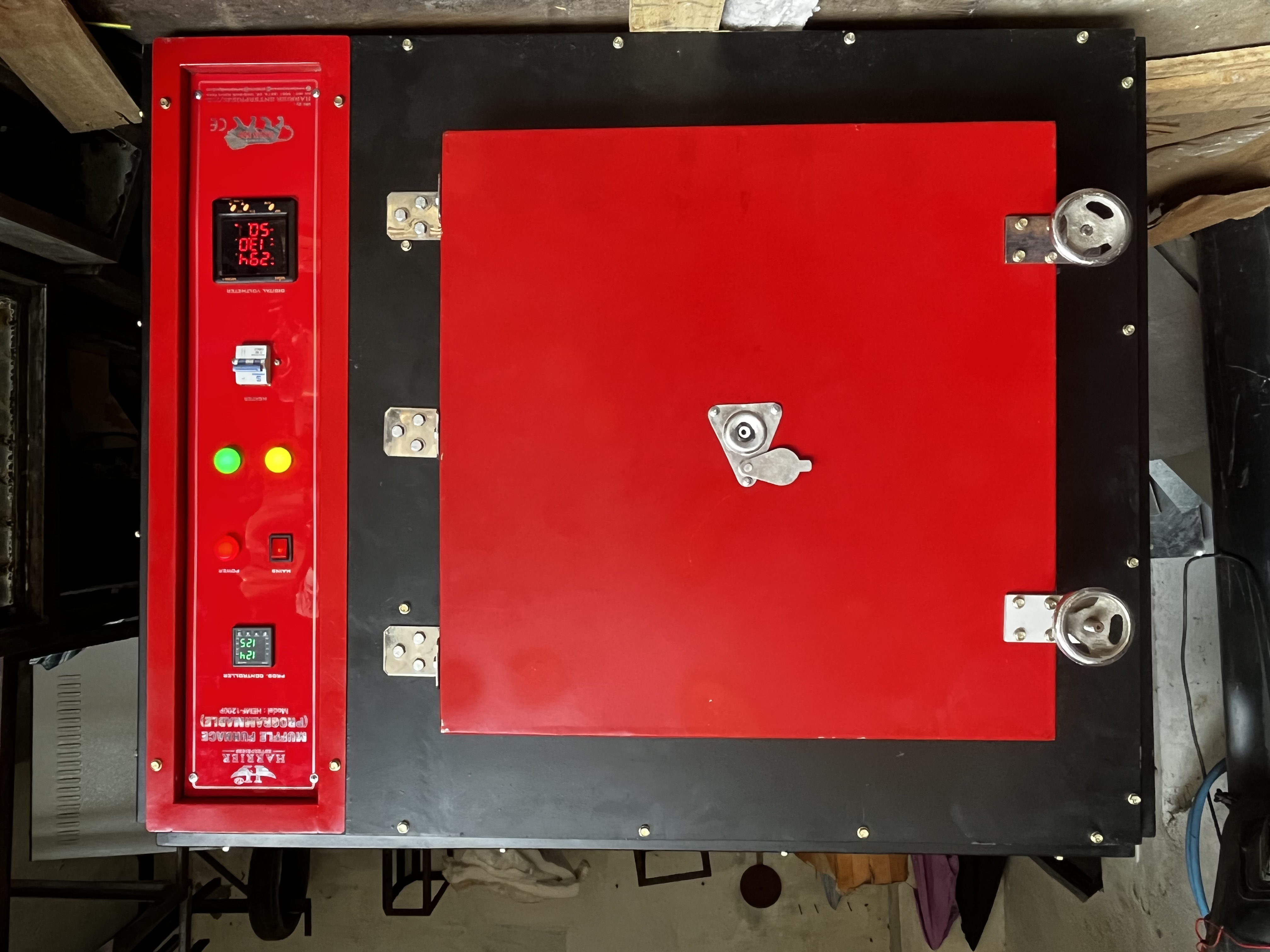

Muffle Furnace (Programmable):- Make: HE ( NSIC REGD, ISO 9001 – 2015/14001-2015/13485-2016/FDA/ GMP/CE CERTIFIED ) Application:- 1200°C Muffle Furnace (Box Type Resistance Furnace) Mainly Provides High Temperature Heat Treatment Environment for Industrial Colleges, Research Institutes, Factories and Other Industrial Laboratories, And Is Applied to New Materials Such As Metal Materials, Ceramic Materials, Nano Materials, And Semiconductor Materials. Features:- The Furnace Material Is Vacuum-Formed Alumina Ceramic Fiber Material And Does Not Drop Powder In High Temperature; Heat Capacity Is Small, Energy Saving Above 50%. The Heating Element Is Made Of High-Quality Kanthal “A-1” Grade as Heating Element, Which Can Bear Low Load, Stable And Long Service Life; The Kanthal APM Grade Is Evenly Arranged On Both Sides Of The Furnace, And The Temperature Field Uniformity Is Good. The Heating Rate Is Fast, From Room Temperature To 1150 Degrees, Generally Takes 120 Minutes. High Precision of Temperature Accuracy ±1°C. PID automatic control via SSR power control with phase angle fired, current limiting resistor. 1 programmable x 16 segments for precise control of heating rate, cooling rate and dwell time. Built in PID Auto-Tune function with overheating & broken thermocouple broken protection for this Muffle Furnace 1400 type. Over temperature protection and alarm allows for operation without attendant Electronic Components Are Used Such As Autonics / Schneider / L&T Brand, its Safe And Reliable. The Machine Will Send Out An Alarm Signal To The Over-Temperature During The Working Process, And Automatically Complete The Protection Action. When The Instrument Program Is Set, Just Press The Run Button And The Next Work Will Be Completed Automatically. Product Overview:- HE-MF 1200℃ Series Products Are Mainly For The Daily Application Development of The Laboratory, High-Quality Furnace Materials And Stable Temperature Control System To Ensure The Reliability of The Experiment; The Product Uses Light weight ceramic Fiber wool insulation (instead of Brick insulation) As The Furnace Material, And The Kanthal “A-1” Is Used For Heating Element, And The Temperature Controller Uses Microprocessor PID Control Module To Achieve Precise Temperature Control And Constant Temperature Requirements Specification:- Type: Table Top Max Temperature: 1200℃ Continue Operating Temp. 1150℃ Heating Element: Kanthal “A-1” Grade Wire in Coil Form Insulation First layer: 1430℃ ceramic fiber board& Zirconia Fiber Blanket. Second layer: 1260℃ ceramic fiber board & Zirconia Fiber Blanket. Triple Layer: High Quality Ceramic Fiber Zirconia Grade Thermal Insulation Material To Ensure A Good Uniformity Temperature Accuracy: ±1℃ Thermocouple: K type (Pt-Rh) with 99.7% purity Alumina tube Temperature Controller PID automatic control via SSR power control with phase angle fired, current limiting resistor. 1 programmable x 16 segments for precise control of heating rate, cooling rate and dwell time. Built in PID Auto-Tune function with overheating & broken thermocouple broken protection for this Muffle Furnace 1400 type. Over temperature protection and alarm allows for operation without attendant Electronic Component Autonics / Schneider / L&T Electronics Brands Heating Rate: ≤ 15℃/Min (Suggest 0℃ TO 10℃/Min For Longer Life Using of Furnace) Safety Protection Overheat And Thermocouple-Break Alarm Certification: NSIC REGD, ISO 9001 – 2015/14001-2015/13485-2016/FDA/ GMP/CE CERTIFIED Furnace Shell: High Quality GI Sheet With PP Powder Coated Warranty One-year limited warranty for this Muffle Furnace 1200 type with lifetime support. (Consumable parts such as heating elements and Sensor, crucibles are not covered by the warranty, please order the replacement at related products) ATTENTION: Any damages caused by the use of corrosive and acidic gases are not under the coverage of One Year Limited Warranty. Using Attentions The cooling rate for this Muffle Furnace 1200 type shall also not exceed 10℃ /min. Toxic or explosive gases are not recommended for use with this furnace without necessary safety controls and supervision. Small cracks may appear on the surface of the refractory ceramics over extended use. This is a normal occurrence and the cracks may be repaired with alumina coating. Refractory door block must be inserted before closing door.

Send Message